Tunnel Machines

Walking excavators have been a critical component in the tunnel construction industry for many decades and Exc@v8 are proud to be a part of that, helping to deliver successful projects with the Menzi Muck product throughout the world for many years.

We are specialists in providing equipment and solutions for escalator, cross-passage and small diameter drive works where conventional methods and equipment are uneconomical, unsuitable or unsafe.

Our unique depth of experience of preparing, mobilising and delivering tunnel-ready excavators to all types of tunnel project from Drill and Blast to Sprayed Concrete Lining means that we have the knowledge and capability to select the correct machine for your project, integrate with your teams to deliver training packages and information, deliver on time at the correct phase of your project and stand by the machine and attachments with a 24hr service support programme helping to ensure that you deliver on-time and on budget.

Exc@v8's winning formula for tunnel excavation has ensured we have been the chosen partner for many high profile and award winning projects throughout the UK and beyond and we are regularly called upon for consultancy and equipment provision for tunnel works throughout the world.

We are specialists in providing equipment and solutions for escalator, cross-passage and small diameter drive works where conventional methods and equipment are uneconomical, unsuitable or unsafe.

Our unique depth of experience of preparing, mobilising and delivering tunnel-ready excavators to all types of tunnel project from Drill and Blast to Sprayed Concrete Lining means that we have the knowledge and capability to select the correct machine for your project, integrate with your teams to deliver training packages and information, deliver on time at the correct phase of your project and stand by the machine and attachments with a 24hr service support programme helping to ensure that you deliver on-time and on budget.

Exc@v8's winning formula for tunnel excavation has ensured we have been the chosen partner for many high profile and award winning projects throughout the UK and beyond and we are regularly called upon for consultancy and equipment provision for tunnel works throughout the world.

Menzi Muck M540 Tunnel Excavator

The Menzi Muck M5 all-terrain mobile excavator is the pocket-rocket of the tunnelling industry. The M5 class machine has been utilised on many tunnel construction projects and is an ideal partner for schemes with a combination of escalator drives, cross passages and chambers. The M540/545 gives high mobility through the site whilst being capable of working on very steep gradients and carrying the most productive of attachments.

With low weight and high drive power combined with unrivalled lifting forces and hydraulic power the M5 series is capable of carrying and driving attachments more commonly seen in the 30 tonne weight class.

The Menzi Muck M5 is known within the tunnel industry for being the most productive power unit for road-header or rockwheel operation in its class and can also be combined with heading buckets, drilling equipment and shotcrete manipulators to give a high power, high utilisation machine.

With low weight and high drive power combined with unrivalled lifting forces and hydraulic power the M5 series is capable of carrying and driving attachments more commonly seen in the 30 tonne weight class.

The Menzi Muck M5 is known within the tunnel industry for being the most productive power unit for road-header or rockwheel operation in its class and can also be combined with heading buckets, drilling equipment and shotcrete manipulators to give a high power, high utilisation machine.

Menzi Muck M525B-TM Tunnel Excavator

The Menzi Muck M525B-TM is the ultimate station construction machine.

Developed specially by Exc@v8 for escalator drive excavation, the -TM designation walking excavator has many special features for the tunneling industry; from its additional rear claws enabling the machine to climb in both directions to the ability to fit winching and deflector pulley equipment to both ends, 6 auxiliary hydraulic circuits featuring the renowned Menzi Powerline for attachments with high-power requirements, the LEXAN-glass cabin, unique FOPS cage with retractable screen guarding and the 60,000 lumens of LED lighting equipment, the M525B-TM is the perfect partner for the most challenging of projects.

This specialised unit also allows escalators to be driven uphill at any angle and without a pilot tunnel - a major step forward in escalator construction, giving the fastest and most cost effective solution for specialist SCL construction projects.

Developed specially by Exc@v8 for escalator drive excavation, the -TM designation walking excavator has many special features for the tunneling industry; from its additional rear claws enabling the machine to climb in both directions to the ability to fit winching and deflector pulley equipment to both ends, 6 auxiliary hydraulic circuits featuring the renowned Menzi Powerline for attachments with high-power requirements, the LEXAN-glass cabin, unique FOPS cage with retractable screen guarding and the 60,000 lumens of LED lighting equipment, the M525B-TM is the perfect partner for the most challenging of projects.

This specialised unit also allows escalators to be driven uphill at any angle and without a pilot tunnel - a major step forward in escalator construction, giving the fastest and most cost effective solution for specialist SCL construction projects.

Wimmer 'Blue Badger' Compact Tunnel Excavator

A compact excavator for maximum safety and precision in tunnel excavation.

The BLUE BADGER® from Wimmer is a tunnelling machine specially developed for applications in connection with the "New Austrian Tunnelling Method". It is the preferred option where space is limited and is therefore particularly suitable for tunnel cross-sections from Ø 3.5m in height. The boom and its mobility is used for a flexible and wide range of applications in tunnel construction.

- Special tunnel swivel arm with 2 x 45 ° swivel bearing

- Optimum lateral routing of hoses and lines

- Wimmer quick coupler for easier tool changing

- Special cylinder arrangement for better component protection

- Kinetics of the boom optimised for tunnel driving

The BLUE BADGER® from Wimmer is a tunnelling machine specially developed for applications in connection with the "New Austrian Tunnelling Method". It is the preferred option where space is limited and is therefore particularly suitable for tunnel cross-sections from Ø 3.5m in height. The boom and its mobility is used for a flexible and wide range of applications in tunnel construction.

- Special tunnel swivel arm with 2 x 45 ° swivel bearing

- Optimum lateral routing of hoses and lines

- Wimmer quick coupler for easier tool changing

- Special cylinder arrangement for better component protection

- Kinetics of the boom optimised for tunnel driving

Menzi Muck 65RD Dumper with rotating cabin

The wheel dumpers of Menzi's own design and production have considerably higher engine performance than other brands with the same payload. The engines of the wheel dumpers comply with all current exhaust gas standards and are already equipped for future regulations.

The turnable safety cabin ensures that the operator is always facing the direction of travel and additional cameras can be added for further enhanced vision in confined spaces.

- Power: 136hp

- Payload: 6300 kg

- 180° turnable cab

- Swivel skip

Accessories: High output auxiliary hydraulics, flat platform with twistlocks, 3-way tipper, further possibilities upon request.

The turnable safety cabin ensures that the operator is always facing the direction of travel and additional cameras can be added for further enhanced vision in confined spaces.

- Power: 136hp

- Payload: 6300 kg

- 180° turnable cab

- Swivel skip

Accessories: High output auxiliary hydraulics, flat platform with twistlocks, 3-way tipper, further possibilities upon request.

Morath Shotcrete Manipulator

The Morath SM653H Shotcrete Manipulator allows the Menzi Muck tunnel excavator to effectively spray-line escalator barrels, cross passages and other tunnel areas leading to higher asset utilisation and lower equipment requirements.

- High degree of flexibility and functionality

- Rollover gear for 360° rotation of the spray nozzle

- Gear to slew the spray nozzle for + / - 90°

- Hydraulic nutation (eccentric motion)

- Hydraulic multiport swivel

- Robust designed framework construction with load hook; suitable for depositing

- High serviceability

- Functional principle: wet mix method

- Without any electrical components

- High degree of flexibility and functionality

- Rollover gear for 360° rotation of the spray nozzle

- Gear to slew the spray nozzle for + / - 90°

- Hydraulic nutation (eccentric motion)

- Hydraulic multiport swivel

- Robust designed framework construction with load hook; suitable for depositing

- High serviceability

- Functional principle: wet mix method

- Without any electrical components

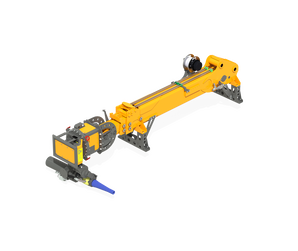

Morath TeleSPRAY

Combined with the Menzi Muck telescopic arm the TeleSPRAY by Morath gives over 13 metres of nozzle outreach, allowing the effective spraying of uphill-driven escalator barrels, wide diameter tunnels and other hard to reach areas. The TeleSPRAY can also be combined with standard excavators for shotcrete application where a robot would normally be required.

- Two stage telescope with well protected, internal feed cylinder and hydraulic lines

- Automatic sprig hose drum, for electrical power supply

- Rollover gear for 360° rotation of the spray nozzle

- Gear to slew the spray nozzle for + / - 90°

- Hydraulic nutation (eccentric motion)

- Hydraulic multiport swivel

- Functional principle: wet mix or dry mix method (interchangeable spray heads)

- For flexible use of different carrier machines with two hydraulic circuits

- Simple joystick installation of remote control through battery power supply only

- Two stage telescope with well protected, internal feed cylinder and hydraulic lines

- Automatic sprig hose drum, for electrical power supply

- Rollover gear for 360° rotation of the spray nozzle

- Gear to slew the spray nozzle for + / - 90°

- Hydraulic nutation (eccentric motion)

- Hydraulic multiport swivel

- Functional principle: wet mix or dry mix method (interchangeable spray heads)

- For flexible use of different carrier machines with two hydraulic circuits

- Simple joystick installation of remote control through battery power supply only

Wimmer W-Lock & OilMaxx Couplers

The Wimmer W-Lock couplers are a solid favourite in tunelling and other tough areas of application due do their simplicity of design and incredibly strong build characteristics. Used extensively in tunnel construction worldwide, their track record speaks for itself.

- Solid, simple construction

- Reverse of attachment tools (bucket reversal) possible

- 100% backlash-free thanks to patented (patent no. US 7,198,451 B2) cone locking system

- Hydraulic force reversal, thus no jamming

- Safety circuit and continuous pressurisation of the interlocking device

The Oilmaxx variant of the W-Lock allows automatic changing of hydraulic tools without the requirement for the operator to leave the cab, leading to increased uptime, a safer working environment and ensuring that the correct tool for the task in hand is always selected without hesitation.

- Solid, simple construction

- Reverse of attachment tools (bucket reversal) possible

- 100% backlash-free thanks to patented (patent no. US 7,198,451 B2) cone locking system

- Hydraulic force reversal, thus no jamming

- Safety circuit and continuous pressurisation of the interlocking device

The Oilmaxx variant of the W-Lock allows automatic changing of hydraulic tools without the requirement for the operator to leave the cab, leading to increased uptime, a safer working environment and ensuring that the correct tool for the task in hand is always selected without hesitation.

Wimmer Tunnel Heading & Loading Buckets

Wimmer manufacture specialist and technically sophisticated tools in the field of tunnel construction and the Wimmer tunnel heading buckets are globally renowned for their aggressive approach angles and uncomparable durability in extreme environments.

- Completely made of special wear-resistant steel WHD 450

- Special design enables backcatching in the tunnel profile

- Design and dentition are adapted to the geology

- Tooth position straight or oblique

- More than 20 years of experience in building tunnel buckets

- Equipped as standard with Esco Ultralock tooth system

Wimmer tunnel loading buckets are optimally shaped to give maximum loading capacity and self-cleaning properties whilst retaining the hard wearing reputation of all Wimmer equipment.

Wimmer tunnel loading buckets are available with a quick-attach front apron.

- Completely made of special wear-resistant steel WHD 450

- Special design enables backcatching in the tunnel profile

- Design and dentition are adapted to the geology

- Tooth position straight or oblique

- More than 20 years of experience in building tunnel buckets

- Equipped as standard with Esco Ultralock tooth system

Wimmer tunnel loading buckets are optimally shaped to give maximum loading capacity and self-cleaning properties whilst retaining the hard wearing reputation of all Wimmer equipment.

Wimmer tunnel loading buckets are available with a quick-attach front apron.