Forestry Equipment

The Exc@v8 Group of Companies are the sole importers of the Menzi Muck, HSM Hohenloher Spezial-Maschinenbau, Konrad Forsttechnik and Seve forestry equipment brands into the UK.

These companies have long legacies of supplying equipment for use in forestry, Menzi Muck from 1966, HSM from 1967 and Seve can trace their legacy back as far as 1970. Today after many decades of evolution and technological advancement these three companies represent the very pinnacle of high-output specialist equipment, especially where there is a requirement for use in steep, difficult access or confined areas. With this in mind it is with great pride that we represent these brands and service their equipment and customers throughout the UK.

These companies have long legacies of supplying equipment for use in forestry, Menzi Muck from 1966, HSM from 1967 and Seve can trace their legacy back as far as 1970. Today after many decades of evolution and technological advancement these three companies represent the very pinnacle of high-output specialist equipment, especially where there is a requirement for use in steep, difficult access or confined areas. With this in mind it is with great pride that we represent these brands and service their equipment and customers throughout the UK.

Menzi Muck Harvester

Profitable, mechanical timber harvesting in challenging terrain has been made possible by the Menzi Muck harvester. With a chassis that adapts to the terrain, a powerful all-wheel drive and the ability to walk the machine over and around obstacles, there is nothing that can stop the Menzi Muck harvester as it even copes with slopes of up to and beyond 100%.

Regardless of whether it is used for storm damaged timber, targeted thinning or clear-fell applications, its range of operation is versatile. The Menzi Muck can also be equipped with excavator accessories for infrastructure tasks to additionally increase its scope of operation and efficiency.

Regardless of whether it is used for storm damaged timber, targeted thinning or clear-fell applications, its range of operation is versatile. The Menzi Muck can also be equipped with excavator accessories for infrastructure tasks to additionally increase its scope of operation and efficiency.

In comparison to other forestry equipment the Menzi Muck harvester is very light-weight and yet also very powerful which has positive ecological effects. Chassis adaptations and low ground bearing pressure protect forest terrain. The agility of the Menzi Muck also prevents damage to remaining forest populations.

The Menzi Muck Harvester allows mechanised felling and processing to take place in areas not previously thought viable or even possible. There is no requirement for access roads or infrastructure and no gradient is too steep - the Menzi Muck can quite literally access all areas.

The Menzi Muck Harvester allows mechanised felling and processing to take place in areas not previously thought viable or even possible. There is no requirement for access roads or infrastructure and no gradient is too steep - the Menzi Muck can quite literally access all areas.

| exc_menzi-muck-forest-machines_0120.pdf | |

| File Size: | 1116 kb |

| File Type: | |

HSM Hohenloher Spezial-Maschinenbau

HSM are renowned and revered throughout the world for producing exceptionally high quality, long service forest machines. Along with production of their well-known harvesters and forwarders, HSM have a reputation for building the toughest yet most advanced skidding tractors, special forestry haulers and unique combination forwarders.

They are pioneers of winch-assist technology, constructing and marketing winch equipped harvesting and extraction equipment for many decades. HSM were the first to incorporate fully integrated synchronised traction winches into their equipment allowing harvesting and extraction equipment to access slopes and areas where before such equipment was inconceivable. Their synchro-winches became so successful that HSM even began to supply their competitors with such equipment and today the 'Force-Synchro-Drive' winches are available as a standalone unit for fitment to machines of all marques.

They are pioneers of winch-assist technology, constructing and marketing winch equipped harvesting and extraction equipment for many decades. HSM were the first to incorporate fully integrated synchronised traction winches into their equipment allowing harvesting and extraction equipment to access slopes and areas where before such equipment was inconceivable. Their synchro-winches became so successful that HSM even began to supply their competitors with such equipment and today the 'Force-Synchro-Drive' winches are available as a standalone unit for fitment to machines of all marques.

| hsm_overview_en.pdf | |

| File Size: | 5964 kb |

| File Type: | |

HSM 405H Harvesters

The HSM 405H harvester is available as an 8-wheel machine in various H2, H3 and H4 versions. When the product was launched on the market many years ago, HSM committed itself to offering high quality products in the range of harvester machines as well. Today, the success speaks for itself. Without exception, the high performance level of our forest technology, impressive quality standards and the highest level of reliability were carried over to the HSM 405H harvester.

The HSM 405H range of harvesters are above-average machines developed for forestry management work. Technologically advanced with exceptional build quality and the very high levels of robustness which can only come from decades of experience in the construction of skidding machines and large-timber extraction equipment.

Download the product sheet for a full specification overview.

The HSM 405H range of harvesters are above-average machines developed for forestry management work. Technologically advanced with exceptional build quality and the very high levels of robustness which can only come from decades of experience in the construction of skidding machines and large-timber extraction equipment.

Download the product sheet for a full specification overview.

| hsm_405h_en.pdf | |

| File Size: | 2365 kb |

| File Type: | |

HSM 208F Forwarders

Narrow design with wide tyres – this basic principle of all HSM forestry machinery has proven to be particularly effective in the development of our crane forwarders. This is reflected in the high load capabilities and the very high level of ground protection.

Whether 208F or 904F, all of the models from the HSM forwarder series stand for inventive engineering with their state-of-the-art drive technology, efficiency and customer-orientated design. Above all, the 208F steep slope version is currently in a league of its own.

With our experience in the construction of crane forwarders, we are at your service to provide reliable, economical harvesting technology adapted to the latest harvesting techniques.

Whether 208F or 904F, all of the models from the HSM forwarder series stand for inventive engineering with their state-of-the-art drive technology, efficiency and customer-orientated design. Above all, the 208F steep slope version is currently in a league of its own.

With our experience in the construction of crane forwarders, we are at your service to provide reliable, economical harvesting technology adapted to the latest harvesting techniques.

| hsm_208f_en.pdf | |

| File Size: | 978 kb |

| File Type: | |

HSM 208F Bigfoot

HSM adheres to the concept of creating "Wide wheels on a vehicle with a small width" like no other manufacturer.

The 208F 10t to 12t model series was equipped with extremely wide tyres of up to 940 mm with a small outer width of under 3 m at its market launch many years ago. This leads to advantages such as:

This enables productive and efficient timber harvesting with less track depth on wet surfaces that would otherwise be impassable. Operating a BigFoot without tracks is efficient and conserves resources. Higher driving speeds and less fuel consumption, all while protecting forest paths (through less erosion of soil), are definite advantages for achieving efficiency.

The 208F 10t to 12t model series was equipped with extremely wide tyres of up to 940 mm with a small outer width of under 3 m at its market launch many years ago. This leads to advantages such as:

- - Less track depth on wet surfaces

- - Higher driving speed and less fuel consumption than vehicles with tracks

- - Significantly less erosion of soil onto the paved forest road

This enables productive and efficient timber harvesting with less track depth on wet surfaces that would otherwise be impassable. Operating a BigFoot without tracks is efficient and conserves resources. Higher driving speeds and less fuel consumption, all while protecting forest paths (through less erosion of soil), are definite advantages for achieving efficiency.

| hsm_208f_bigfoot_en.pdf | |

| File Size: | 1538 kb |

| File Type: | |

HSM Combination Forwarders

HSM combination forwarder machines are available in various performance categories and versions. They feature a wide range of applications.

Long or short timber – hardwood or softwood – thick trees or thin. The solution for diverse application scenarios in timber harvesting are "combination machines" from HSM. Whether you opt for the combination version or the short chassis version, timber harvesting measures can be performed with extreme efficiency and at the highest level of work quality with different types of material or lifting operations at various locations.

The result is perfectly presented and offers the customer a formidable performance package despite irregular framework conditions. The success of our customers also relies on a forwarding quality that assures subsequent orders. Providing support for this success still remains HSM's main objective.

The basic models HSM 805F – HSM 904F and HSM 208F can all be offered as short chassis (KC) or combination versions.

HSM has therefore developed a convincing modular system that permits the implementation of customer-specific requirements while keeping procurement costs reasonable.

Long or short timber – hardwood or softwood – thick trees or thin. The solution for diverse application scenarios in timber harvesting are "combination machines" from HSM. Whether you opt for the combination version or the short chassis version, timber harvesting measures can be performed with extreme efficiency and at the highest level of work quality with different types of material or lifting operations at various locations.

The result is perfectly presented and offers the customer a formidable performance package despite irregular framework conditions. The success of our customers also relies on a forwarding quality that assures subsequent orders. Providing support for this success still remains HSM's main objective.

The basic models HSM 805F – HSM 904F and HSM 208F can all be offered as short chassis (KC) or combination versions.

HSM has therefore developed a convincing modular system that permits the implementation of customer-specific requirements while keeping procurement costs reasonable.

|

|

| ||||||||||||||||||

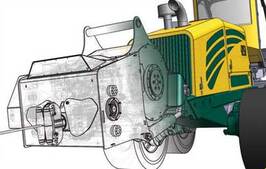

HSM Special Forestry Hauler

Widely revered as the worlds ultimate skidding tractor, this special forestry hauler range gives high production and a large range of work method possibilities combined with the exceptional reliability and durability which has helped forge the HSM name.

HSM 805 or HSM 904: each performance category of our haulers offers options for a diverse range of applications. Whether crane body or classic cable hauler, we offer individual solutions to suit your requirements.

Crane body haulers provide an excellent platform for energy, shear and harvester head mounting whilst the classic cable haulers have a wide range of winch options. Both can be equipped to tow forestry trailers making your HSM special forestry hauler the ultimate all-rounder.

More than 50 years of experience in the manufacture and sale of forestry machinery show that quality, service friendliness and customer orientation of our special forestry haulers meet the highest standards.

HSM haulers stand for innovation, economic operation and environmentally-friendly technology – anywhere in the world.

HSM 805 or HSM 904: each performance category of our haulers offers options for a diverse range of applications. Whether crane body or classic cable hauler, we offer individual solutions to suit your requirements.

Crane body haulers provide an excellent platform for energy, shear and harvester head mounting whilst the classic cable haulers have a wide range of winch options. Both can be equipped to tow forestry trailers making your HSM special forestry hauler the ultimate all-rounder.

More than 50 years of experience in the manufacture and sale of forestry machinery show that quality, service friendliness and customer orientation of our special forestry haulers meet the highest standards.

HSM haulers stand for innovation, economic operation and environmentally-friendly technology – anywhere in the world.

|

|

| ||||||||||||||||||

HSM Force-Synchro Drive winches

Until recently, fully mechanised short timber technology was not available for steep slopes. As a result, there is now a strong demand for suitable, high performance machinery that operates with as little ground damage as possible on sharp gradients at risk of erosion.In recent years, HSM has spurred on steep gradient technology for wheel machines with several innovative solutions and invested further in this technology to satisfy the growing demands of its customers and to contribute towards their success.

The "Force Synchro Drive" from HSM has helped HSM to make enormous strides forward. It was introduced for the first time in 2010 with the HSW-15 auxiliary traction winches.

The increased cable capacity, the higher cable pulling forces and the more powerful drive system with optimised efficiency facilitate safe and quick manoeuvring on steep gradients. With up to 15 tonnes of pull, the Force Synchro Drive will keep you safe and productive even in the worst terrain.

The "Force Synchro Drive" from HSM has helped HSM to make enormous strides forward. It was introduced for the first time in 2010 with the HSW-15 auxiliary traction winches.

The increased cable capacity, the higher cable pulling forces and the more powerful drive system with optimised efficiency facilitate safe and quick manoeuvring on steep gradients. With up to 15 tonnes of pull, the Force Synchro Drive will keep you safe and productive even in the worst terrain.

Woody Harvester Heads

The WOODY unit by Konrad Forsttechnik is suitable for both harvesting and processing alternatively, as well as purely a harvesting unit on a pick up loader. With its grab action, the WOODY can load and stack timber as well as prepare it for easy transport by hauling cable/skyline.

The unique and patented frame geometry of the WOODY makes the processing of foliage, trees and crooked timber possible.

The WOODY can be used in combination with an alpine harvester or harwarder (a combination of harvester and forwarder), a walking excavator type harvester as well as more commonly found dedicated harvester units and tracked excavator based harvesters.

The WOODY's retractable, upward folding feed rollers allow it to be used as a fully functional loading grapple with wide opening and endless rotation at the flick of a switch, allowing the handling and loading of multiple logs.

At Exc@v8 we manufacture the Konrad design of 'Walking Leg' under licence here in the UK for fitment

to tracked excavators using harvester heads. Contact us to find out more.

The unique and patented frame geometry of the WOODY makes the processing of foliage, trees and crooked timber possible.

The WOODY can be used in combination with an alpine harvester or harwarder (a combination of harvester and forwarder), a walking excavator type harvester as well as more commonly found dedicated harvester units and tracked excavator based harvesters.

The WOODY's retractable, upward folding feed rollers allow it to be used as a fully functional loading grapple with wide opening and endless rotation at the flick of a switch, allowing the handling and loading of multiple logs.

At Exc@v8 we manufacture the Konrad design of 'Walking Leg' under licence here in the UK for fitment

to tracked excavators using harvester heads. Contact us to find out more.

Seve T-Raz

The Seve T-Raz is an incredibly powerful radio-controlled tracked power unit for mowing, mulching and clearing work in poor access areas, rough terrain and on steep slopes.

The radio controlled T-Raz can comfortably work all land in natural areas, on bankings and steep ground thanks to its long track frame and exceptionally low center of gravity. Even wetlands and soft ground are no problem with this units low ground pressure and optional integrated winch.

A single user performs the work of many persons in comparison to manual brush-cutting and vegetation removal, or even compared to a team of small excavators.

The T-Raz carries a fixed tooth high-output Seve mulcher allowing it to successfully handle mature whole-trees, large-stemmed vegetation and even complete stumps.

The T-Raz can perform other duties typically carried out by a hydraulic skid unit, only with much greater productivity and effectiveness due to it's high horsepower and huge hydraulic output. Large stump grinders and snow blowers are examples of interchangeable tools.

This unit has to be seen to be believed. The hugely powerful T-Raz quite literally eats the competition for breakfast.

- Engine: Deutz TCD 3.6 L4

- Power: 136hp at 2300 rpm

- Torque: 500Nm at 1650 rpm

The radio controlled T-Raz can comfortably work all land in natural areas, on bankings and steep ground thanks to its long track frame and exceptionally low center of gravity. Even wetlands and soft ground are no problem with this units low ground pressure and optional integrated winch.

A single user performs the work of many persons in comparison to manual brush-cutting and vegetation removal, or even compared to a team of small excavators.

The T-Raz carries a fixed tooth high-output Seve mulcher allowing it to successfully handle mature whole-trees, large-stemmed vegetation and even complete stumps.

The T-Raz can perform other duties typically carried out by a hydraulic skid unit, only with much greater productivity and effectiveness due to it's high horsepower and huge hydraulic output. Large stump grinders and snow blowers are examples of interchangeable tools.

This unit has to be seen to be believed. The hugely powerful T-Raz quite literally eats the competition for breakfast.

- Engine: Deutz TCD 3.6 L4

- Power: 136hp at 2300 rpm

- Torque: 500Nm at 1650 rpm

| t_raz_2_seve_eng.pdf | |

| File Size: | 10534 kb |

| File Type: | |

HSM CTL250-FR Forest Crawler

The CTL250-FR Forest Crawler from HSM is a versatile and economical machine for small-scale timber extraction and the presentation of inaccessible trees for mechanical harvesters.

The low centre of gravity combined with the parallel rear plate (including height adjustable rope guides - 250 mm) ensure high stability even when carrying out demanding rope work.

The Forest Crawler is therefore ideally suited for deployment on critical slopes and in areas which are hard to access. The specially manufactured track mechanism with bogie pendel wheels guarantees excellent traction even in rough terrain. In addition the Forest Crawler can be equipped with an easily removable front traction winch which has synchronous power control and a tractive power of up to 2.3t, along with plentiful power to drive the proportional rear ADLER EHY-5 winch.

The Forest Crawler can be deployed quickly and easily - it can be transported on a car trailer as it is only 1700 mm wide and has a total weight of 2.5t.

The low centre of gravity combined with the parallel rear plate (including height adjustable rope guides - 250 mm) ensure high stability even when carrying out demanding rope work.

The Forest Crawler is therefore ideally suited for deployment on critical slopes and in areas which are hard to access. The specially manufactured track mechanism with bogie pendel wheels guarantees excellent traction even in rough terrain. In addition the Forest Crawler can be equipped with an easily removable front traction winch which has synchronous power control and a tractive power of up to 2.3t, along with plentiful power to drive the proportional rear ADLER EHY-5 winch.

The Forest Crawler can be deployed quickly and easily - it can be transported on a car trailer as it is only 1700 mm wide and has a total weight of 2.5t.

| hsm_ctl_250fr_exc.pdf | |

| File Size: | 1542 kb |

| File Type: | |

Cable Yarders

Konrad MOUNTY truck mounted skyline/tower-yarder and processing unit

The Mounty truck mounted skyline and processing unit allows high levels of production output to be achieved in steep terrain and poorly accessible areas. The self contained Mounty allows the timber to be felled and then the 'whole tree' to be brought by skyline - uphill or down - to the yarding area where the Mounty is situated. From there the Mounty's crane can de-limb, cut to length, sort and stack the timber ready for hauling away. It can be used in conjunction with either the Woodliner or Liftliner carriage units and allows the entire high-capacity extraction and processing operation to be carried out by just two people.

- Fuel saving technology - Fast and easy setup

- Comfortable cabin - Compact construction

- Ergonomic and safe workplace

- High tower

- Fuel saving technology - Fast and easy setup

- Comfortable cabin - Compact construction

- Ergonomic and safe workplace

- High tower

Konrad KMS trailed skyline/tower-yarder

The KMS 4000 is a radio-controlled cable crane which is mounted on a tandem trailer.

This allows the processor operator (often an excavator based unit with WOODY head) to have complete control over both the tower-yarder and the carriage by radio remote, eliminating the need for additional operators and groundsmen. To enhance productivity the KMS has a fully automatic control system which allows the carriage to travel to preset points without supervision.

The KMS approach combines a high degree of safety with class-leading productivity.

- Automatic travelling of the carriage

- Road towable at high speed

- Convenient operation of the entire system via radio control

- Compact design

- Powerful haulback

This allows the processor operator (often an excavator based unit with WOODY head) to have complete control over both the tower-yarder and the carriage by radio remote, eliminating the need for additional operators and groundsmen. To enhance productivity the KMS has a fully automatic control system which allows the carriage to travel to preset points without supervision.

The KMS approach combines a high degree of safety with class-leading productivity.

- Automatic travelling of the carriage

- Road towable at high speed

- Convenient operation of the entire system via radio control

- Compact design

- Powerful haulback

Konrad Liftliner radio-controlled skyline/yarder carriage

The LIFTLINER radio-controlled skyline carriage is a safe and highly productive solution to haul-back cable-yarding.

With the new radio-controlled carriage LIFTLINER 4000 it is possible to operate the hoist and travel functions simultaneously. This gives a very smooth and efficient operation with minimal waiting time at either end.

Due to the LIFTLINER having its own radio-controlled load-winch with 100m of cable, the yarder winch becomes a dedicated haul-back line, only being used to move the carriage along the skyline cable. With the haul-back line not having to pass through the carriage as it would with a slack-pulling system, yarder winch and cable wear is kept to a minimum, prolonging cable and component life.

With the new radio-controlled carriage LIFTLINER 4000 it is possible to operate the hoist and travel functions simultaneously. This gives a very smooth and efficient operation with minimal waiting time at either end.

Due to the LIFTLINER having its own radio-controlled load-winch with 100m of cable, the yarder winch becomes a dedicated haul-back line, only being used to move the carriage along the skyline cable. With the haul-back line not having to pass through the carriage as it would with a slack-pulling system, yarder winch and cable wear is kept to a minimum, prolonging cable and component life.

For more information on our range of forestry products please contact us on [email protected] or fill out a contact form and

we will get back to you soon!

we will get back to you soon!